| Page: |

| Home > Show Us Yours! > K1100 turbo track car build | |||||||

539 Posts Member #: 6807 Post Whore York |

15th Sep, 2015 at 10:05:16am

Some more progress over the last few weeks.

|

||||||

7263 Posts Member #: 1268 The Boom Boom speaker Police! Essex |

15th Sep, 2015 at 11:00:03am

Looking fantastic. In the 13's at last!.. Just |

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

15th Sep, 2015 at 11:53:59am

I'm liking the reversed cooling setup, that idea might get stolen! lol

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

539 Posts Member #: 6807 Post Whore York |

15th Sep, 2015 at 12:11:10pm

On 15th Sep, 2015 Joe C said:

I'm liking the reversed cooling setup, that idea might get stolen! lol the intercooler might have worked better as a double pass, both pipes at the top... more room for a duct to the front Cheers for the encouragement chaps. I did consider a twin pass arrangement but it worked out quite a bit worse for pressure drop after spinning the calcs. The lower hose is about 60mm away from the core right at the back of the end tank and angled away from the face of it. Plenty of room to fit the final section of the duct down there between them. PS. cooling system patent pending

Edited by adcyork on 15th Sep, 2015. |

||||||

4890 Posts Member #: 1775 Post Whore Chester |

15th Sep, 2015 at 05:29:07pm

Going to be a high quality car! Loving the interior I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

539 Posts Member #: 6807 Post Whore York |

16th Sep, 2015 at 12:58:10pm

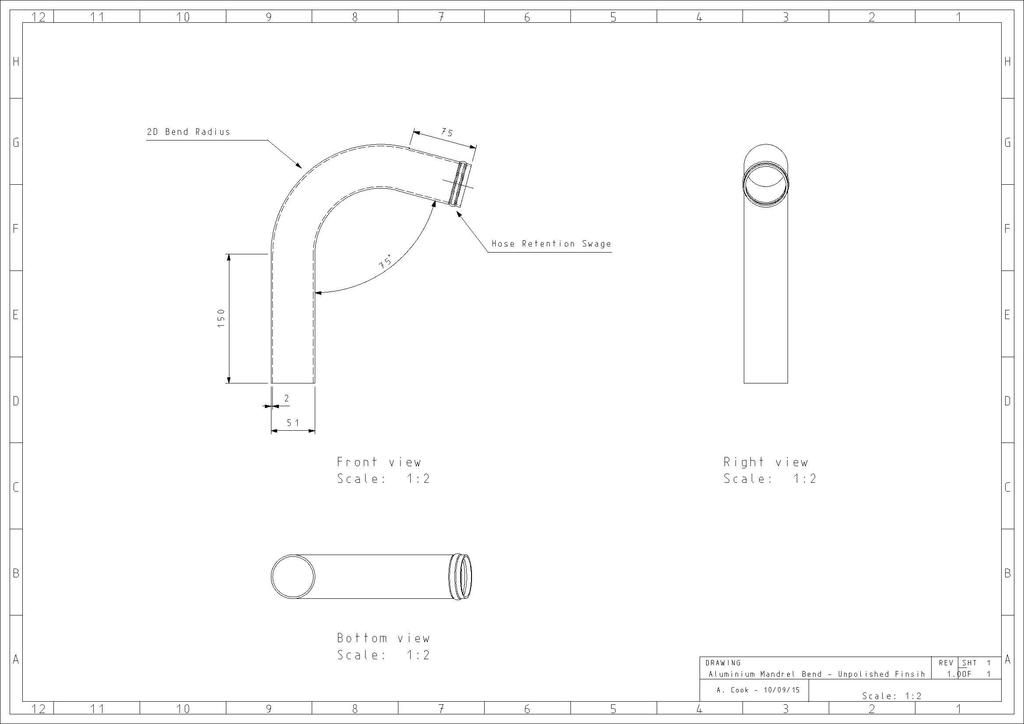

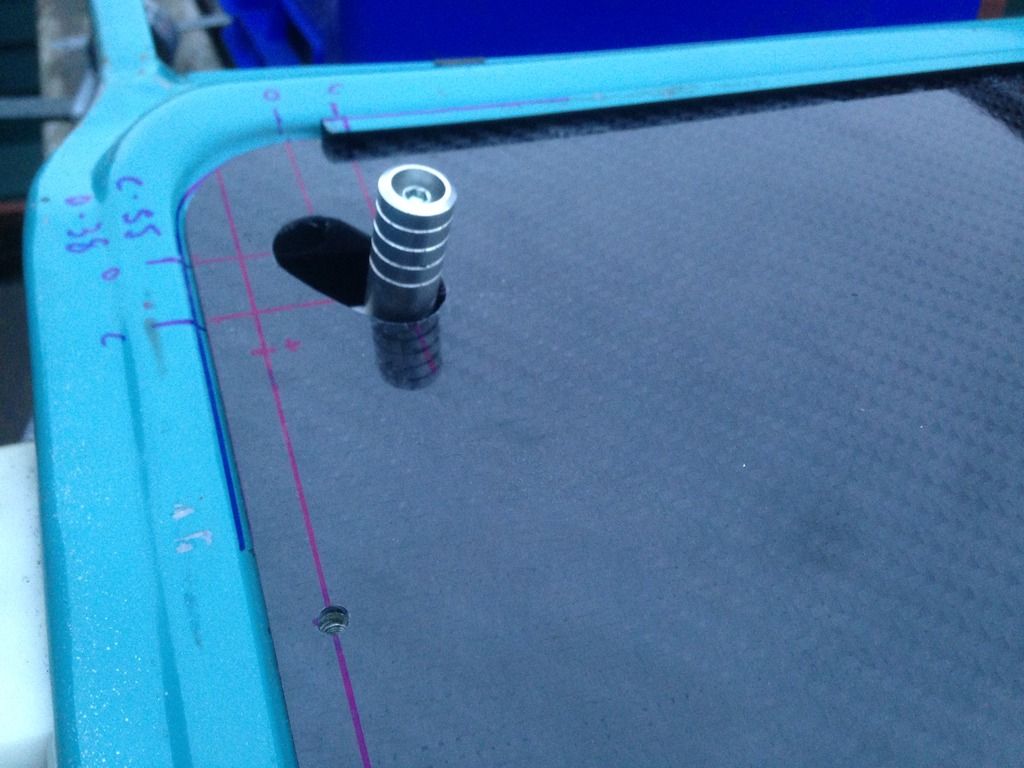

I've hit a bit of a snag with the intercooler pipework.

Edited by adcyork on 16th Sep, 2015. |

||||||

|

Site Admin  9401 Posts Member #: 58 455bhp per ton 12 sec 1/4 mile road legal mini Sunny Bridgend, South Wales |

16th Sep, 2015 at 02:22:43pm

some nice work here, whats the plans with the car, race car or track day? We are always looking for more minis in the welsh Saloon car championship Team www.sheepspeed.com Racing

On 15th May, 2009 TurboDave said:

I think the welsh one has it right! 1st to provide running proof of turbo twinkie in a car and first to run a 1/4 in one!! Is your data backed up?? directbackup.net one extra month free for all Turbo minis members, PM me for detials |

||||||

243 Posts Member #: 1261 Senior Member Droitwich |

16th Sep, 2015 at 09:20:01pm

Try this guy maybe, when i was asking him about custom rollcage he said £15 per bend and the T45 tubing i was asking for was 20 per meter.. so based on that id say 160 is outrageous

|

||||||

539 Posts Member #: 6807 Post Whore York |

17th Sep, 2015 at 06:48:32am

Jim, plan is for it to be a track car that would only need a fire extinguisher fitting to make it eligible for MSA race series yes. I've been keeping my eye on the WSCC. Are all the races held at Pembrey?

On 16th Sep, 2015 JetBLICK said:

Try this guy maybe, when i was asking him about custom rollcage he said £15 per bend and the T45 tubing i was asking for was 20 per meter.. so based on that id say 160 is outrageous http://www.tube-bender.co.uk/ I found this guy during a google for places around coventry as he's only round the corner. He can't do this in aluminium though... cheers for the suggestion though |

||||||

|

Site Admin  9401 Posts Member #: 58 455bhp per ton 12 sec 1/4 mile road legal mini Sunny Bridgend, South Wales |

17th Sep, 2015 at 08:05:31am

most of them are at pembrey, but there is a meeting at combe and looking else where too Team www.sheepspeed.com Racing

On 15th May, 2009 TurboDave said:

I think the welsh one has it right! 1st to provide running proof of turbo twinkie in a car and first to run a 1/4 in one!! Is your data backed up?? directbackup.net one extra month free for all Turbo minis members, PM me for detials |

||||||

539 Posts Member #: 6807 Post Whore York |

13th Oct, 2015 at 03:49:38pm

Managed to get some time to take some meat out of the inner door skins with the holes saw, fit the door cards up and work out a solution to the door release without using the heavy orignial mechanism that I can't reach with the harnesses done up.

|

||||||

673 Posts Member #: 1395 Post Whore chepstow |

15th Oct, 2015 at 10:35:18pm

looking good! |

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

16th Oct, 2015 at 09:19:10am

Love the craftsmanship and attention to detail. |

||||||

539 Posts Member #: 6807 Post Whore York |

20th Oct, 2015 at 07:50:25am

Well, I've received the stainless pipe for the turbo outlet but it seems i've cocked up the measurements. It needed to be 120deg bend not 105deg as I'd measured - too many things not fixed down properly when i was measuring up.

|

||||||

2091 Posts Member #: 9894 Post Whore Dorking |

20th Oct, 2015 at 12:37:09pm

Try these guys, I have a couple from them for coolant.

|

||||||

|

Site Admin  15300 Posts Member #: 337 Fearless Tom Fenton, Avon Park 2007 & 2008 class D winner & TM legend. |

20th Oct, 2015 at 01:41:59pm

I've not used them personally, but I have seen cars with their hoses fitted which seem OK, try Roose Motorsport in Lincoln, it would appear they manuafacture their own hoses, not just buying stuff in.

On 29th Nov, 2016 madmk1 said:

On 28th Nov, 2016 Rob Gavin said:

I refuse to pay for anything else Like fuel 😂😂 |

||||||

84 Posts Member #: 10547 Advanced Member Northern Ireland |

7th Nov, 2015 at 05:42:13pm

Hi mate, what kind of pedal box are you using? and what ratio is it? Instagram: bighill93

|

||||||

|

336 Posts Member #: 9941 Senior Member Derby |

8th Nov, 2015 at 08:16:13am

Theres also a silicone hose place in burton on trent! Called Derby performance hose! Good guys if you ring them they make virtually anything to order with reasonable turn around time |

||||||

539 Posts Member #: 6807 Post Whore York |

10th Nov, 2015 at 01:34:17pm

I'm using the wilwood 6.25 ratio reverse mount pedal box.

On 7th Nov, 2015 jayme said:

Hi mate, what kind of pedal box are you using? and what ratio is it? Thanks everyone for the suggestions on where to get the silicone hose. I ended up getting one direct from viper in black which arrived a couple of days later - not the cheapest option but cheaper than anywhere online and it arrived quick so I could test fit it all before I pulled all the subframe etc again to start making the down pipe. I've recently started making the mould for the intercooler duct so I started out with a big block of styrofoam that I rough cut in to something close.

Next up was to make an absolute s**t tip of the work bench top and make a hot wire cutter from whatever I had lying around.

I was thinking that I might need a rheostat to control the current flow to the wire but a quick test with a small 4Ah motorcycle battery showed that the 0.8mm stainless mig wire was a good match for the battery so it didnt need one. Stayed hot enough for about 10 mins cutting before the battery was flat, plenty good enough. Work in progress.

With the subframe and associated gubbins out of the car I've got on with the down pipe and exhaust. Had to take a chunk out of the back of the subframe to clear the 2 1/4" pipe but I've got a plan to chuck some metal back in there to recover some stiffness.

The V-band and wastegate outlet into the down pipe are due to change position so that it will flow better but here it is mocked up

Rear box and centre pipe run before making the mounting ears. Glad I changed that rear spar of the subframe to the stiffer tube with the cut out and integral threads for the bobbins. It's allowed the exhaust to about half an inch higher.

Finished off the mounting solution for the fuel tank aswell. Just needs some ali spreader plates putting under the fixing points in the fibreglass floor panel.

|

||||||

2974 Posts Member #: 10749 Post Whore lowestoft suffolk |

10th Nov, 2015 at 01:58:39pm

Nice work, which exhaust is that? On 24th Oct, 2015 jonny f said:

Nothing gets past Dave lol NOTHING GETS PAST ME!!

1/4 mile 14.7 @ 96mph 12psi boost Showdown class A 2nd place 18.6 @ 69mph |

||||||

539 Posts Member #: 6807 Post Whore York |

10th Nov, 2015 at 02:24:07pm

It's a bespoke setup I've made from individual components, mostly off ebay.

|

||||||

2974 Posts Member #: 10749 Post Whore lowestoft suffolk |

10th Nov, 2015 at 03:49:22pm

Ah yes i may of already asked you that question? Haha, dont suppose u know a link for the box etc.. ive tried searchin but just get tonnes of chavtastic stuff to siv through On 24th Oct, 2015 jonny f said:

Nothing gets past Dave lol NOTHING GETS PAST ME!!

1/4 mile 14.7 @ 96mph 12psi boost Showdown class A 2nd place 18.6 @ 69mph |

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

10th Nov, 2015 at 03:57:02pm

great stuff,

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

2742 Posts Member #: 637 Post Whore Hertfordshire |

10th Nov, 2015 at 07:41:49pm

Lovley manifold chap! My build thread..

|

||||||

539 Posts Member #: 6807 Post Whore York |

11th Nov, 2015 at 08:53:26am

On 10th Nov, 2015 D4VE said:

Ah yes i may of already asked you that question? Haha, dont suppose u know a link for the box etc.. ive tried searchin but just get tonnes of chavtastic stuff to siv through Dont think so but I don't mind answering again. I'm not using the size of box but this is the same seller: http://www.ebay.co.uk/itm/Stainless-Steel-...OwAAOxyeR9TLHP9 Rolled tip: http://www.ebay.co.uk/itm/2-25-Rolled-Out-...LHmbXJECXONmpew On 10th Nov, 2015 Joe C said:

great stuff, one point, what are you doing with the wastegate outlet? open air or feeding into the down pipe? if the latter, consider feeding it in a decent distance after the lambda sensor, as airflow past the valve guide can affect the lambda reading. Cheers for the heads up. Its for this reason I'm using v bands and two bolt flanges instead of slide joints - trying to make every effort to minimise air leaks. The wastegate will be plumbed back into the down pipe as far downstream as possible, the images above were just a mock up with bits I had lying around to check v band clearance to the bulkhead. The sensor will be immediately post turbo and due to the low back pressure 2 1/4" system I am hoping that there won't be much reverse flow |

||||||

| Home > Show Us Yours! > K1100 turbo track car build | |||||||

|

|||||||

| Page: |